Photoelectric sensors for

Lumber Processing Applications

Manufacturer: Pantron Instruments, GmbH

Category: Photoelectric sensors

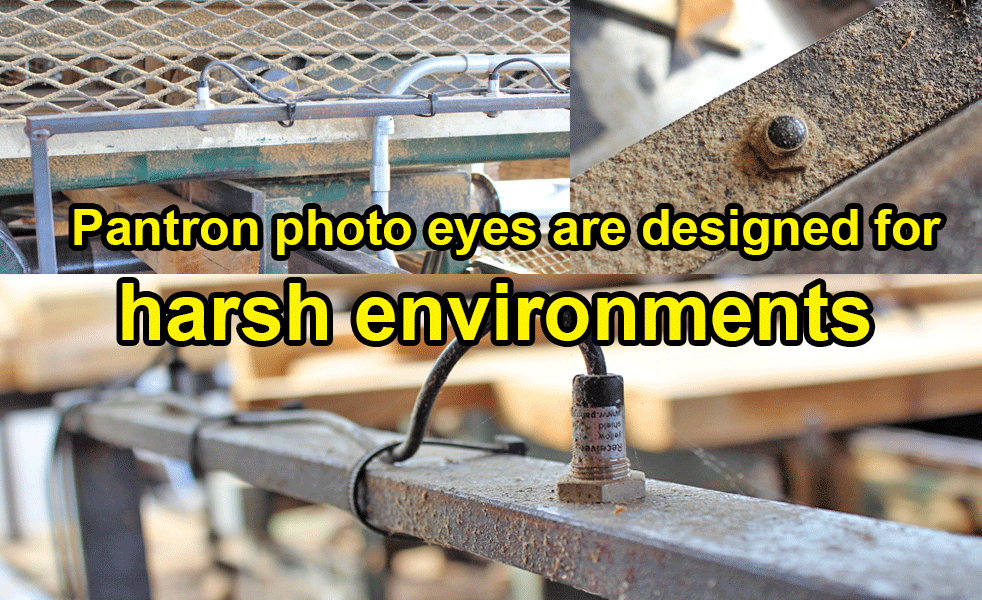

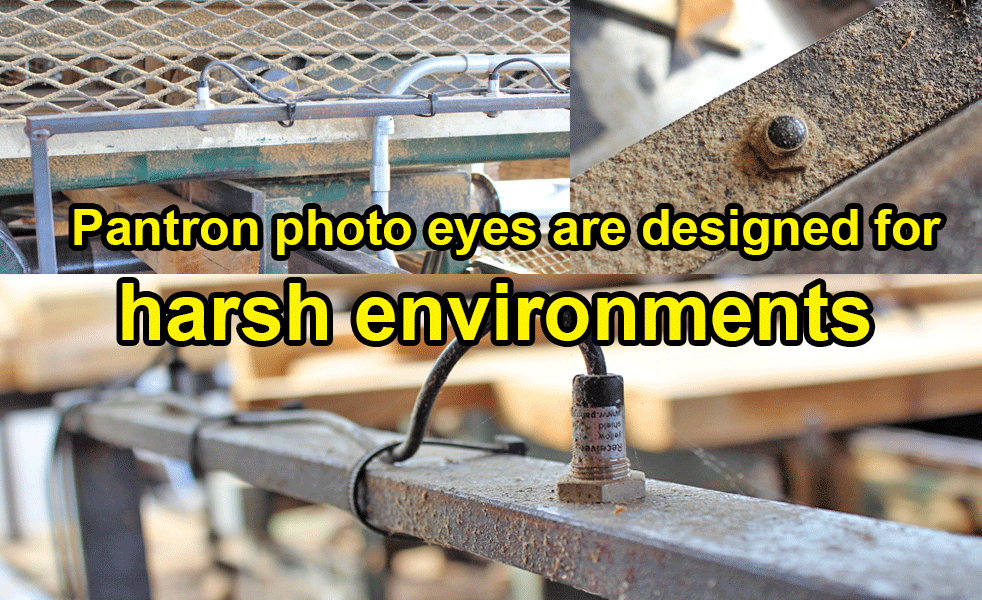

Pantron photoelectric sensors thrive in hostile environments where other sensors fail. In both hardwood and pine lumber mills, Pantron sensors work hard to keep your equipment up and running. Vibration, condensation, dirt, and sawdust are no problem for these sensors.

Pantron Photo Eyes on a 2-saw Edger

This video was created at McDowell Lumber in Asheboro, North Carolina. McDowell Lumber uses Pantron photoelectric sensors for two separate applications on their two-saw edger. A two-channel multiplexer (IMX-N24 series) is used with two sets of photoeyes to detect that a board is loaded properly on the feeding table prior to entering the machine. There is a single set of Pantron photo eyes controlled by a single-channel amplifier (ISG-N24 series) positioned to detect the board as it is exiting the saw. The photo eyes activate the press rolls to keep the board firmly pressed against the rollers.

Detect Height of Boards for Sorting

This video shows a single set of Pantron eyes configured in diffuse and mounted at an angle. They are controlled using a single channel Pantron amplfier (ISG-N24 sweries) The eyes are used to detect logs over a certain height. Smaller boards pass through, while larger logs are detected by the sensors and loaded onto the Cant Deck.

Automatically Feed Boards into Machines

Use Pantron photoeyes to detect the end of a board so that the next board may be automatically fed at the correct time. Dirt, condensation, and vibration won't impair the photo eye's ability to see through.

Contact Mats for Operator Safety

The safety mat systems are available in standard and custom sizes and shapes. They deliver higher performance, unmatched reliability and enhanced safety and comfort for machine operators. Use these contact mats to limit the start function of machines to when the operator is in position and out of harm's way.

Reduce Down-time and Maintenance Costs

All Pantron automatic infrared photoelectric amplifiers and multiplexers are equipped with microprocessor-controlled diagnostic tools. When things do go wrong, the photoelectric system will help the operator quickly and easily diagnose the problem so that it may be corrected. This keeps down-time to a minimum and reduces the need for lenghtly and often costly service calls.

Reduce Cross-Talk and False Signals

Pantron multi-channel infrared amplifiers (multiplexers) are designed to control multiple sets of photo eyes without the possibility of cross talk or false signals between the sets of eyes. Multiplexers are available in 2, 4, and 8 channel versions. The 4 and 8 channel multiplexers may be connected together to provide a synchronized photoelectric system.

Overcome Sunlight

Sunlight poses a difficult problem for most photoelectric sensors in the outdoor applications. Pantron photo eyes are designed with 60,000 LUX immunity to sunlight. Also, the receiver eye looks for the specific frequency of infrared light that is emitted by the transmitter eye and ignores extraneous light sources.